Reflex Wearable

The Reflex wearable system is used to prevent strain-and-sprain injuries at the workplace. It does this by providing real-time feedback (vibration) when a worker is engaging in a risky lifting, twisting, or jumping activity. Also an IoT connected product, the Reflex system will upload additional metadata and telemetry when the device is placed back in it’s charging cradle at the end of a shift. See Kinetic’s Whitepaper for more information about the impact and accomplishments of the Kinetic platform.

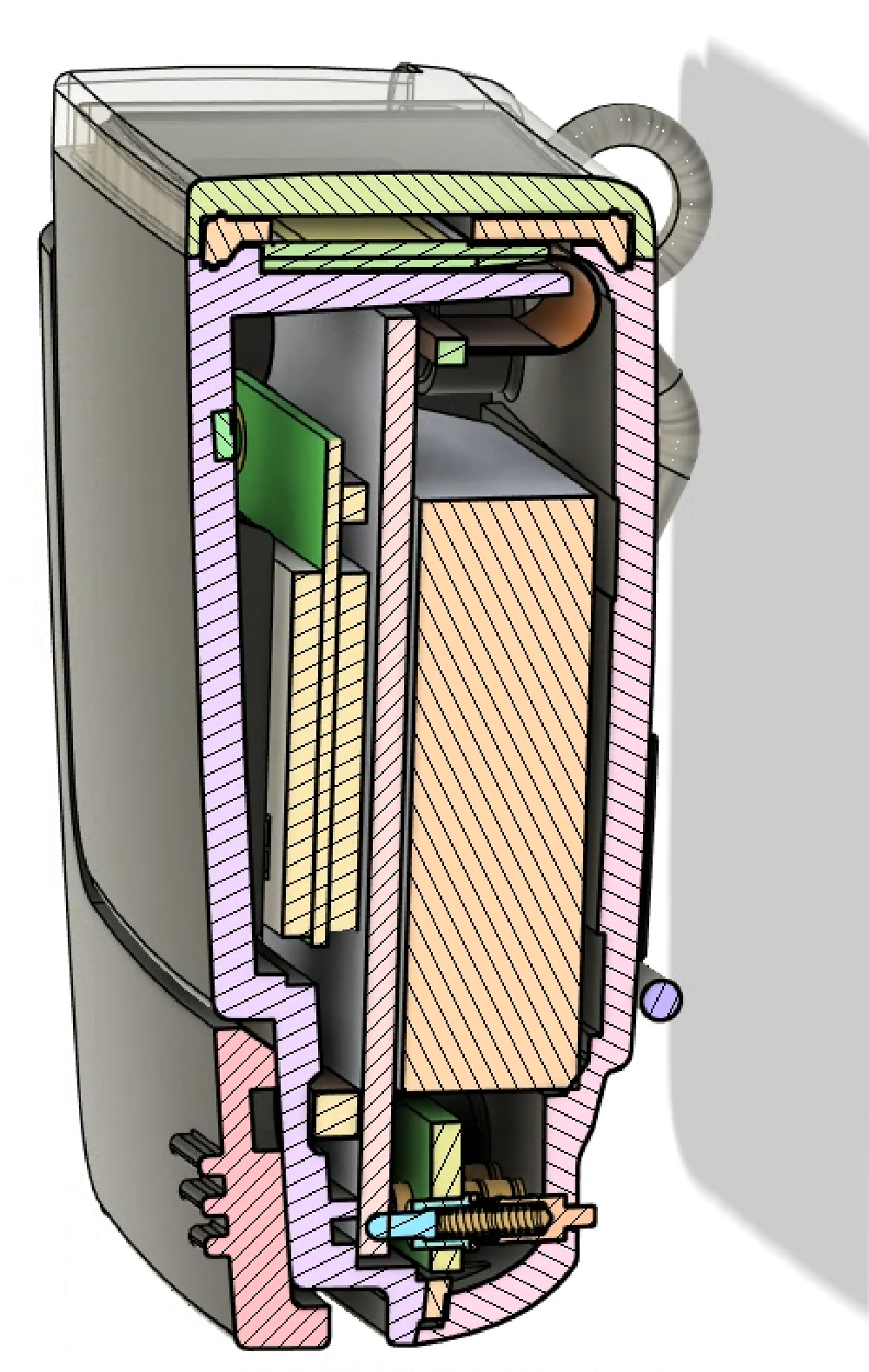

The Reflex wearable uses a smart 6-axis IMU and an altimeter to capture the user’s orientation in space. These datastreams are combined using Kinetic’s custom sensor-fusion algorithm to track changes in activity and orientation consistent with risky postures. An embedded linux SOM is used to collect+store data, run the data processing algorihm, run the UI, and upload results to the cloud via Wifi.

I joined this product just in time to help Kinetic rapidly scale up Reflex production. I rewrote Factory Testing, QC/QA, Battery maintenance and Cellular management processes to ensure consistent quality of product and user experience. I contributed a great many bugfixes to the firmware codebase and to the mechanical assmblies, as well as fleetwide data analysis for preventative battery maintenance. I also lead design of an upgraded next-generation version of the wearable (not pictured here).